Our concrete 3D printing technology, based on ISCEX and a traceability platform, enables accurate, certifiable and sustainable manufacturing.

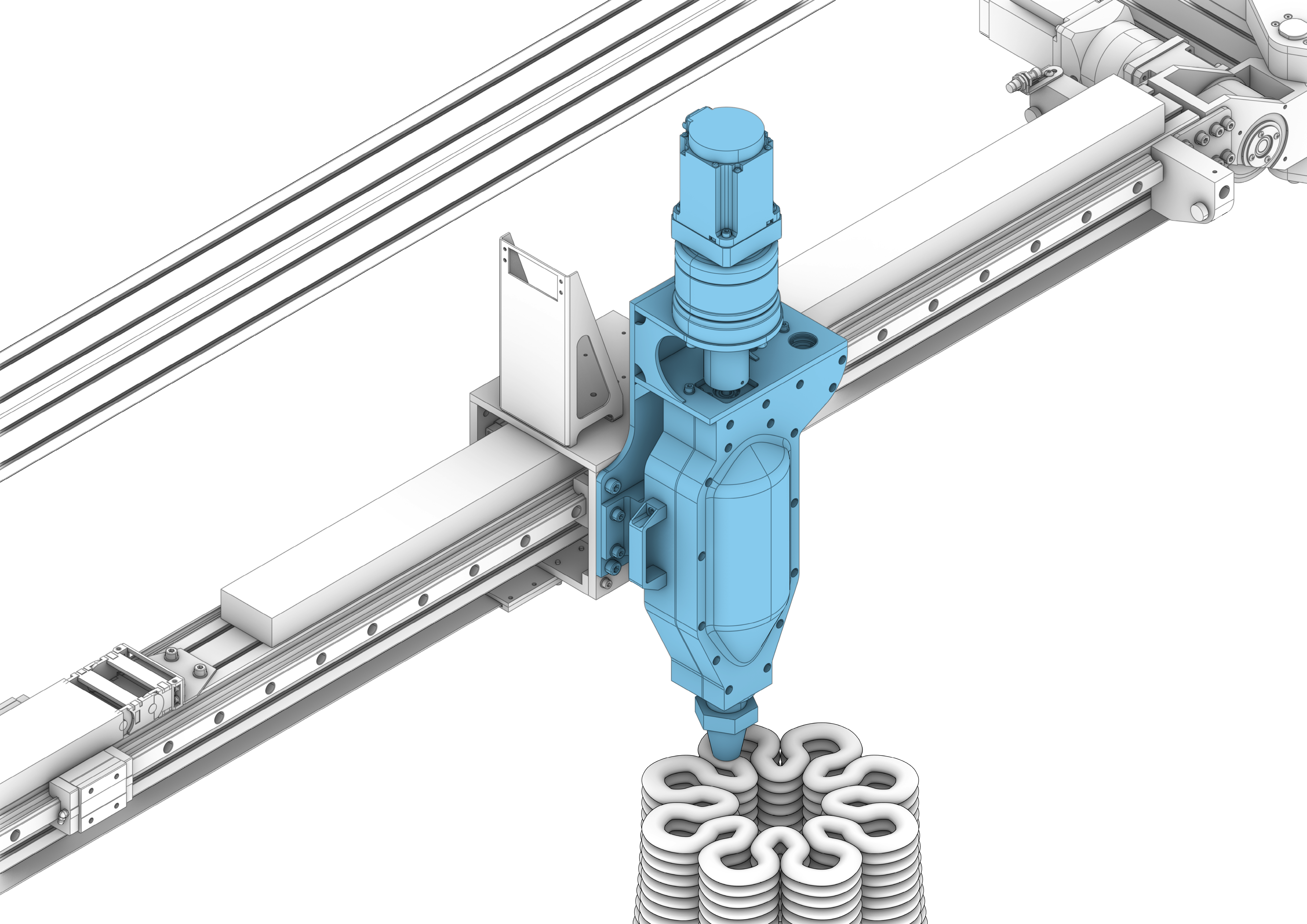

Print head

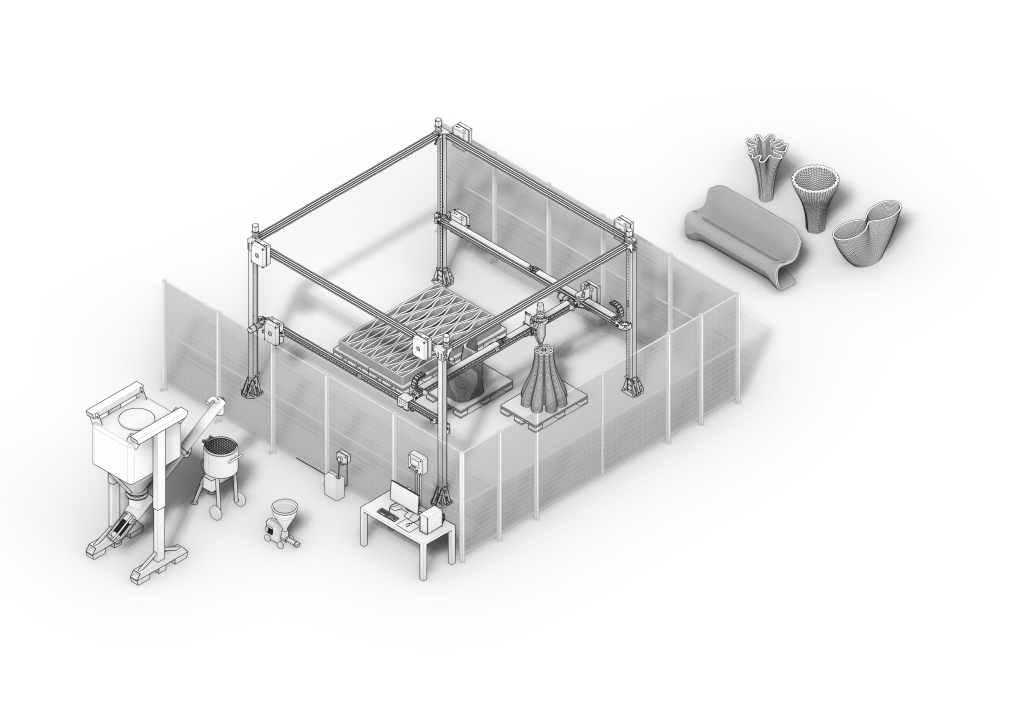

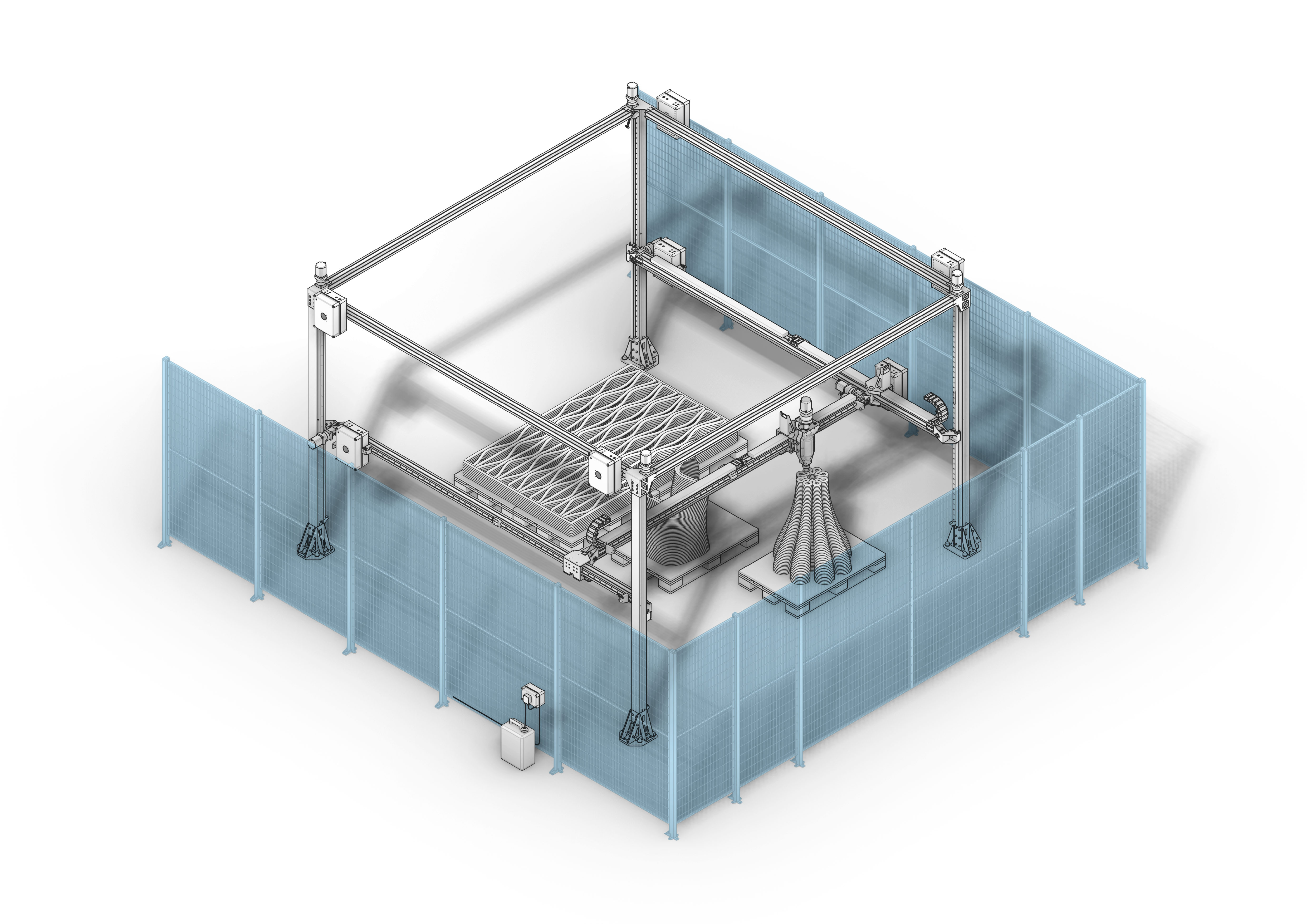

3D Printer

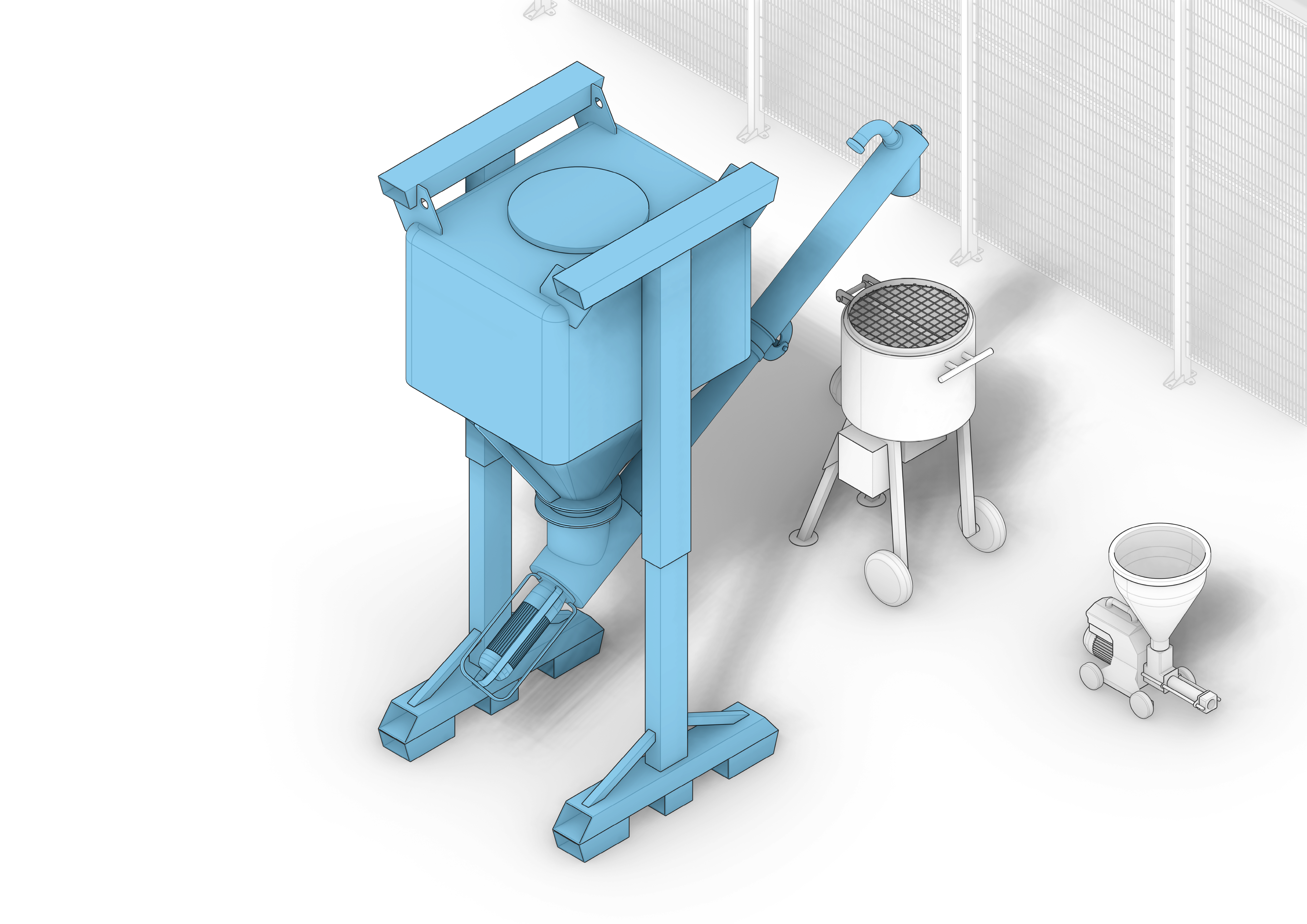

Silo for material

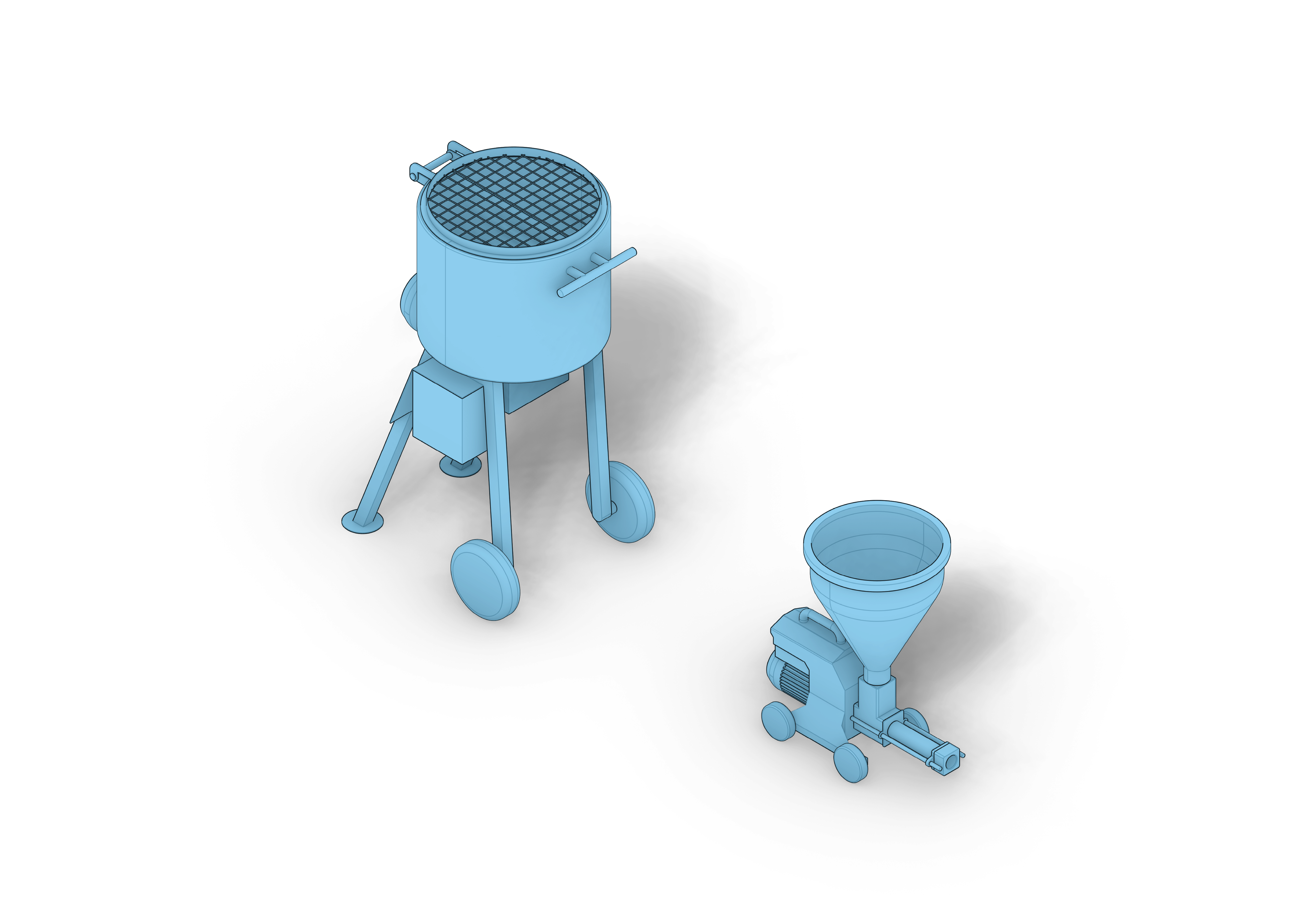

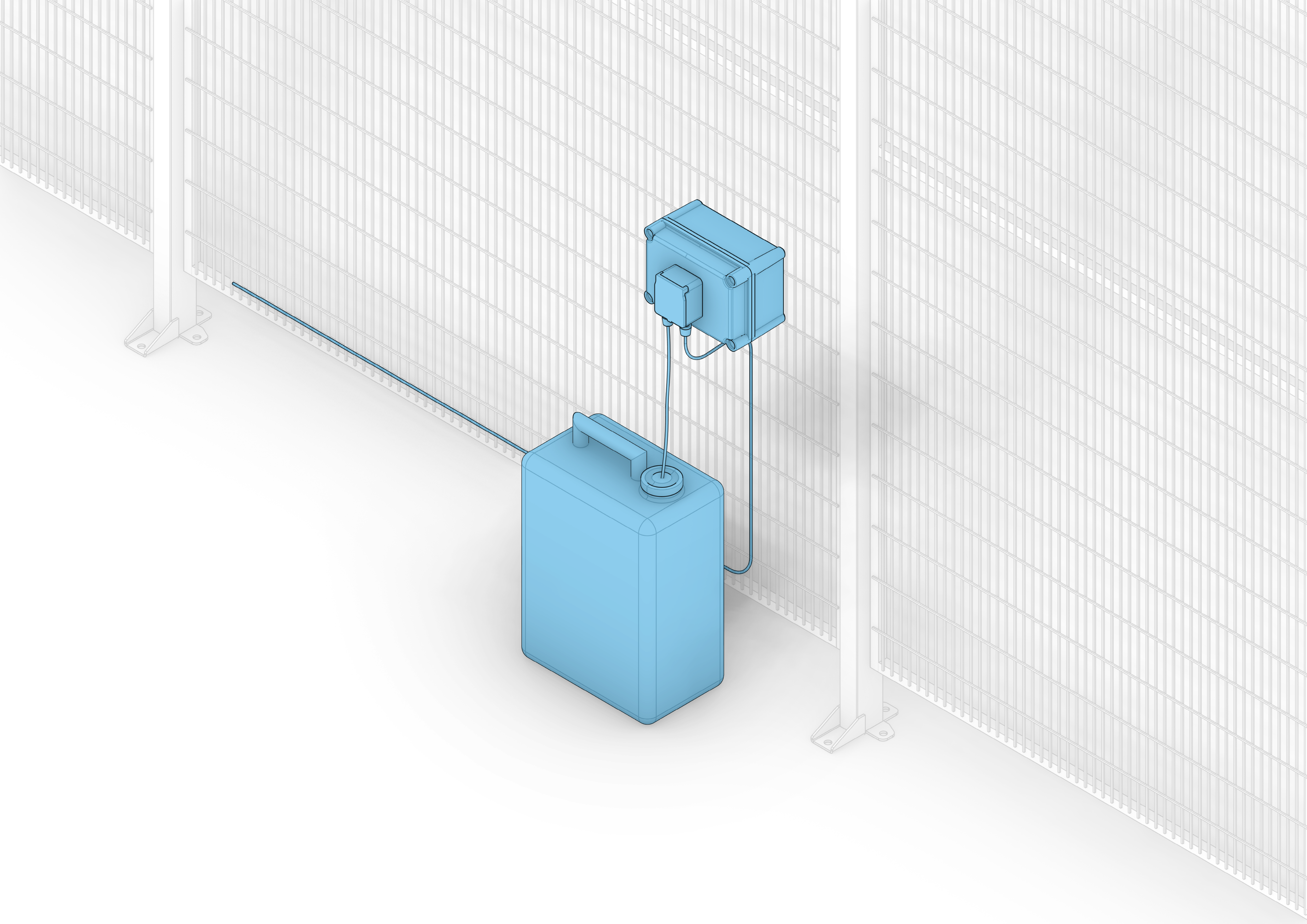

Mixing and pumping

Additive pumping

Security enclosure

Printed lot

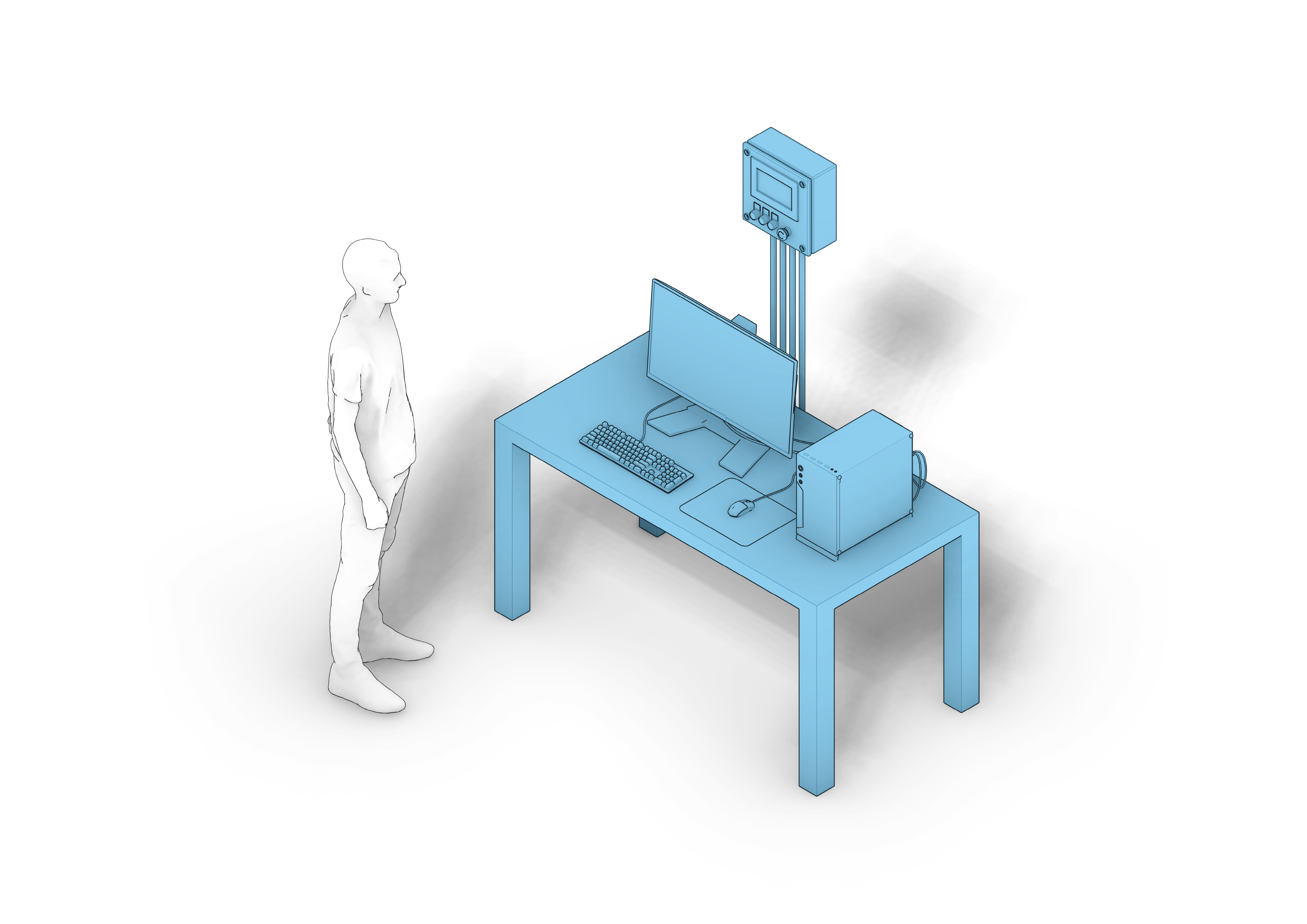

Control

It incorporates proprietary ISCEX (Instant Setting Concrete Extrusion) technology, which allows the depositing of concrete with instant setting, achieving complex geometries without formwork.

Built with world-class components, our printer is robust, reliable and fully customisable to the customer’s needs and production environment.

The silo allows for industrialised production, with minimal dust generation and very low manpower requirements, favouring the complete automation of the process.

The system ensures precise mixing and automatic flow control from the real-time control system, adapting to every geometry and printing rhythm.

The pumping of accelerator additives is completely stable and pulse-free, which ensures constant and controlled dosing at all times.

The enclosure guarantees a safe environment and complies with all CE industrial safety standards, protecting the operator and ensuring process stability.

Each batch produced with the Volta 3D Printer can reach between 1 and 4 tonnes of parts per day, with a fully traceable and validatable process.

The control system not only governs the printer, but interacts with the TRACE cloud platform, recording all process parameters to ensure quality, efficiency and traceability.

TRACE is our traceability technology that ensures that every batch produced has a complete digital record of its manufacturing parameters and materials.

Total control over the quality, certification and traceability of each batch produced.

Assessment of the ecological impact of each lot, promoting transparency and sustainability.

Continuous development of sustainable solutions in 3D printing materials to reduce environmental impact and improve structural properties.